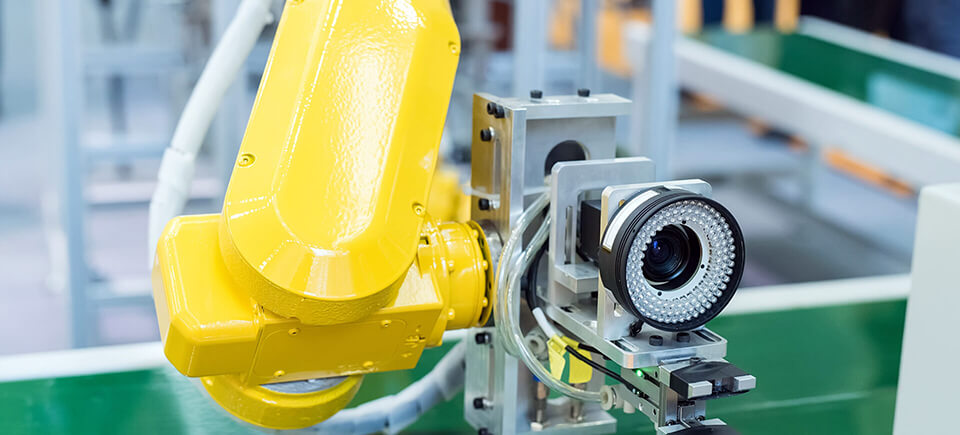

Object recognition software for quality control and worker safety

This famous quote from ‘The Hunger Games’ trilogy is apt in the context of computer vision technology. The basic forms of computer vision technology have been around for decades. Earlier computer vision technology was able to see or record objects, but their interpretation still required human intelligence. Now, with the advent of artificial intelligence, the machines can be trained to know the objects that they see.The computer vision, in particular object recognition algorithms, have boosted automation in various industries. Due to these new abilities, the advances achieved in the manufacturing industry are spectacular.

Unlike in 90’s or ‘00s, today most manufacturing facilities are already well automated. Sensors, cameras, robots, conveyors are helping bring labor to a minimum. Although it may seem that there’s almost no room for process optimization left, recent advances in computer vision are just going to be the main source of tremendous further improvements. In manufacturing, the true ability of machines to see will allow excluding humans from the production process completely, in particular where humans have to work in hazardous conditions. This will raise production capacity to a new level, decreasing costs at the same time.

“Knowing it and seeing it are two different things.”

- Suzanne Collins, Mockingjay

The new generation of computer vision algorithms enable machine to reliably recognize any possible visual object. Since humans can be susceptible to boredom and fatigue, in many cases, computers do object recognition even better than a trained human. Big IT giants realized the true power of automated recognition and are already rapidly implementing these technologies into their core business. As for the manufacturing sector – the situation here is a bit different.

In contrast to big IT companies, often small manufacturers lack the budget and proper specialists to build an in-house object recognition solution. BitRefine group tries to bridge this gap by offering a ready-to-use universal object recognition software, that lets manufacturer automate various tasks. Small manufacturers often have several questions about object recognition software. Here we will discuss the most common questions.

There’re plenty of areas, where both small and big companies can successfully apply object recognition platform. These areas include but are not limited to quality assurance, inventory management, custom object detection, sorting, and monitoring assembly lines.

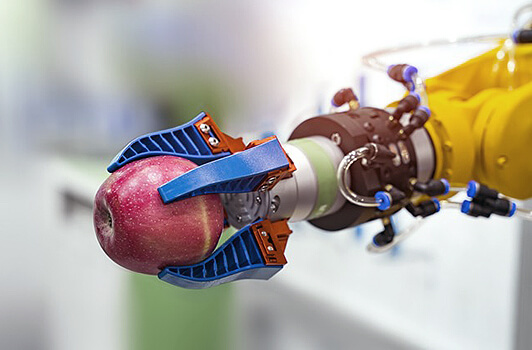

In order to choose one particular area out of the numerous options, many prioritize financial benefits i.e., cost cutting and return on investment. For example, reducing the costs of quality inspection. Automated solutions can do any kind of visual inspection of parts, products, fruits, materials, surfaces instead of employees. A computer vision software based on neural network architecture can successfully work with images or video, captured from different angles even if defects vary greatly in sizes, colors or shapes. Automated inspection system will lead to an increase in productivity, reduce the number of required staff, reducing the load on equipment or inventory needs – in other words, it will result in measurable profit.

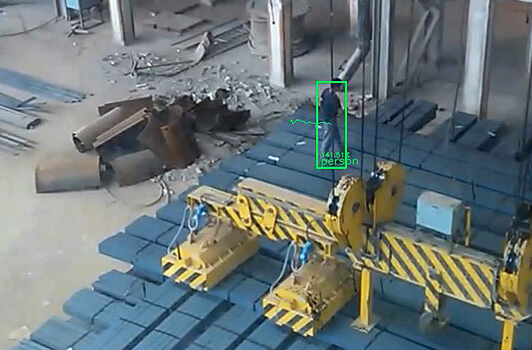

Automated recognition software can also be used to monitor manufacturing facilities. A computer can recognize people, inappropriate actions, certain objects in restricted zones, or do any kind of counting – all the work that that is usually done by supervisors. Automated recognition software doesn’t need a salary, doesn’t lose focus and is always unbiased. This results in measurable cost reduction related to the actions of staff.

Lastly, a company can use automated recognition software for special tasks too. Broadly speaking, you can start thinking of the object recognition system as of your staff. The difference is that this is not a human, but a computer system. If a task is common, a computer can get to work right away. But if you need to recognize a special kind of object or action, then, similar to human, deep learning computer algorithm will need additional training. This is an important feature of all systems, based on artificial neural networks. This additional training may require neural recognition experts. Specialists at BitRefine group do all required training according to client’s requirement and provide the client with a ready-to-use neural recognition module.

What to automate first?

A client usually has a choice: to use specialized software or to choose a multi-purpose solution and configure it for his particular task. For example, an apple sorting facility may use an application designed especially for recognizing certain defects on apples. Advantage of this option is that the client is able to run this solution immediately. The downside is that if the client eventually needs recognizing a different object, say peaches, she will need to search and install different recognition application.

If a client decides to use a single multi-purpose object recognition software, she will need to spend some extra time teaching the system to recognize required defects on apples. This can take a week or two. But recognition platform remains absolutely flexible after that. If a client needs to detect defects on peaches, grapes or tomatoes, she will be able to do additional training and computer will be recognizing any of those objects or all of them at once. Moreover, if eventually client decides, that she needs to recognize other objects such as people, trucks or faces, she can entrust this task to the same multi-purpose platform.

What is the best: multi-purpose platform or specialized recognizer?

Yes, of course, there’re cases, where object recognition software is not useful. A simple way to predict, if modern computer vision algorithm is capable of recognizing a certain object is to ask, if a human is capable of recognizing this object or not. If the answer is yes, computer with an artificial neural network in its core will also be capable to do this.

It is also important to remember, that deep learning object recognition software always detects and classifies objects with a certain probability. For example, if you show a plastic part with an obvious, large scratch on it, the computer will identify it as a scratch with probability 99%. But if the scratch is small, or thin, or poorly lit, or partly occluded, so that even you’re not sure what this is – in such a case computer may still identify it as a scratch but this time with a probability of just 15%. All you have to do is to configure software accordingly: shall it keep such part on a production line or remove it and recycle.

Is there anything that computer vision software can’t recognize?

Expert excerpt: machine vision system based on AI

Classic machine vision software needs hard-coded instructions to find and check a certain object in the image. The instructions are simple if you need to extract, say, a circle from a solid background. But, the more complex the object, the more instructions you need to add. As soon as you start working with real-world objects, such as features on surfaces, it’s almost impossible to build a scope of instructions to have classic machine vision application reliably recognize and classify them.

Machine vision software that is built on neural network architecture doesn’t need instructions. Artificial neural network are trained by presenting examples of target object instead. This is similar to teaching people to distinguish certain plant species by showing photos of them.

The object is recognized. What’s next? The story doesn’t end with the successful recognition of an object. Successful object recognition leads to an improvement in manufacturing in two ways. The penultimate goal of the recognition system is to collect data about observed objects and events. Accurate unbiased statistics is the key to reveal opportunities for improvements in internal business processes. The ultimate goal of the system is an automatic execution of certain action. For example, if a computer sees a defect, it sends a command to a mechanism that will remove a defective part from the line. In some cases, the system needs to send an alarm to personnel, indicating a detected abnormality.

Multi-purpose object recognition software offered by BitRefine group can accomplish both goals, connections to automation hardware and visual data analysis tools. The output obtained from these tools such as the search queries, tables, and charts provide a better picture of manufacturing processes.

Today companies are starting their transformation towards a data-driven business to boost profits and gain competitive advantages. Big data is the core of this transformation. And computer vision is an essential source of such data. Therefore, after some time spent solving particular automation tasks, we’ll see massive integration of computer vision into company-wide data-driven solutions.

Today developers offer recognition platforms either as a SaaS, or as a classic software package. Typical examples of SaaS providers are Google’s Compute Engine, AWS, Microsoft Azure. In case you choose to have computer vision running in the cloud, you simply send images to server using a solution provider’s API. The server then returns to you a list of objects that it managed to recognize. A major advantage of the SaaS approach is that you don’t have to care about buying computing hardware and purchasing software licenses.

However, there are a few downsides. The downsides of computer vision SaaS are:

• you need to do integration of provider’s API before you can transfer images to the cloud

• you need to ensure high-speed uninterruptable internet connection

• if you work with video, SaaS may be inapplicable due to large bandwidth required

• the total amount of paid fees for the SaaS after some time may significantly exceed costs of purchasing a classic software package

If you choose classic software, first you need a powerful computer, usually a high-end machine. Then you install object recognition software, connect cameras or other sources of visual data, configure the system and let it run. Here you need to have a specialist, who will keep an eye on running modules, do maintenance and other services, typical for IT systems. The main advantage of on-premises object recognition solution is that it allows you to work with any type of visual data at any speed.

At BitRefine, we realize that both solutions serve a specific purpose and are therefore valuable. BitRefine offers its computer vision platform both as SaaS solution and as an on-premise software. The client is free to choose an option that better meets her requirement. In a dynamic industry such as manufacturing, a client may be interested in both the solutions. For instance, some clients may want to use SaaS services for a while before they make a commitment to on-premises object recognition solution.

Run recognition in the cloud (SaaS) or on premise

The field of AI machine vision is growing rapidly now. Many developers are already reaching clients with their solutions. This occasionally can overwhelm a business leader to create feelings of anxiety and confusion. Some companies are convinced that they need to use an object recognition system but are not sure which one. Here we offer general guidelines to choose an optimal system from available options.

Machines that can see are able to solve a broad range of tasks. Usually, after successful implementation in one area, a company immediately discovers several new areas, where recognition software would perfectly fit. Therefore, from the very beginning company should give priority to flexible and adaptable platforms over software with a limited list of detectable objects. Flexibility means significant savings in the future.

Another aspect of general flexibility is the ability of recognition software to run on different hardware platforms. Developers of hardware follow the AI trends and keep bringing to the market various computer units, optimized for artificial neural networks. If object recognition software runs on a full-size PC with Windows only, you will not be able to leverage more powerful, yet more compact and cheap hardware units in the future.

Not just computer vision software but also the expert developers behind it is a key consideration. As we mentioned before, neural networks need training. This means that you need either to have an in-house specialist or rely on services provided by an external agency such as a system integrator or developer of computer vision software. If the developer provides not just a recognition platform but also takes responsibility of the client’s particular project – this would be the best choice. In this case, the client needs just to pass footages to developers and fix requirements. The developer will adapt neural network, train it properly and provide the client with a ready-to-go machine.

Guidelines to choose the right object recognition system

Companies are leveraging computer vision to improve three general areas—to increase yields, reduce costs, and gain competitive advantages by integrating AI into the products themselves. Integration of computer vision in various sectors, including manufacturing, is happening at a rapid pace. A conservative estimate suggests that the computer vision industry will reach $26 billion by 2025, while others estimate computer vision industry (hardware and software both) will grow up to $48.6 billion annually by 2022, at a compound annual growth rate (CAGR) of 32.9%. Although in the beginning only big players could afford this kind of technology, now no company can afford to fall behind. Today general purpose, computer vision solutions have removed all previous entry barriers and allowed even a small manufacturing company put artificial intelligence at its service. There is a growing consensus among business leadership that this is the time to include computer vision in manufacturing.

Computer vision industry will grow up to $48.6 billion by 2022.

June 10, 2019